The History of Casters

What are Casters?

Sometimes people use the words “wheel” and “caster” interchangeably, when a wheel is only one component of a caster. A caster is a device containing a wheel that is attached to the bottom of a large object (furniture, trailers, trucks, etc.) in order to move the object more quickly and easily. Using casters makes it possible to pull and push objects rather than carry them.

Casters seem like such simple objects, but try to imagine pushing a shopping cart through a grocery store with no casters on the bottom to help transport your groceries. Or how distressed businessmen in this society would be without casters to roll their fancy swivel chairs around. More importantly, effective health treatment would not be as achievable without casters on hospital beds to transport patients to help save their lives.

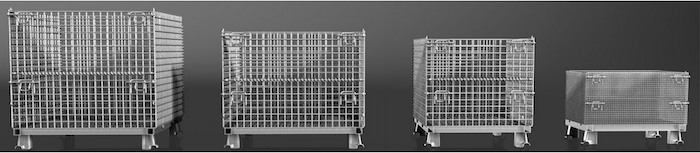

Additionally, casters are crucial in the material handling industry, as can be seen in our wire containers. One of the most imperative desires in material handling involves obtaining the most effective method of transporting extremely heavy bulk packaging.

When were Casters Invented?

Moving large items with wheels has been around since the early existence of ancient civilization. Then many centuries later in 1876, casters were first patented by a man named David A. Fisher, whose invention was initially designed for furniture.

How do Casters Continue to Evolve?

At their initial invention, casters were mainly used for industrial purposes as they were extremely heavy. As they evolved, casters were made from only glass or leather to reduce damage on wood flooring from the sliding.

At their initial invention, casters were mainly used for industrial purposes as they were extremely heavy. As they evolved, casters were made from only glass or leather to reduce damage on wood flooring from the sliding.

Casters today are still made with glass and leather — and many other materials from plastic to iron to anything in between, such as aluminum, stainless steel, rubber, or nylon. Casters are now also designed to include many features such as brakes, direction locks, shock absorbency, and temperature resistance.

What are the Different Types of Casters?

- Rigid Casters: Most basic type of caster. Does not rotate. Designed to move objects in a straight line. Commonly used as the back wheels on a shopping cart

- Swivel Casters: Rotates allowing the object to rotate 360°. For example, the front wheels of a shopping cart

- Industrial Casters: Heavy duty casters designed to transfer up to 30,000 Ibs. Design can incorporate rigid or swivel casters. Dolly carts, for example, use industrial rigid casters

- Braking and Locking Casters: Any type of caster can include a special brake feature, which is low in cost and stops the wheel from turning. It is usually a small lever that can be pulled to stop the object’s movement

What are the Benefits of Casters?

- Makes large objects easier to move

- Moves large objects faster

- Heavy weight capacity

- Minimization of possible injurious effects on operator

- Low in cost

- Durable

- Thousands of different types to choose from

How are Casters Made?

We have already distinguished the different types of casters available and that they can be made out of several types of plastics and metals. The components that make up casters are a mixture of household and industrial items. There are four main designs of casters:

- Compound

- Undriven

- Single

- Double

What came Before Casters?

- Wheels – 4500 BC

- Wagons – 3000 BC

- Cranes – 515 BC

- Pulleys – 287 BC

- Wheelbarrows – 233 AD

- Cardboard Boxes – 1817

What Was Invented at the Same Time as Casters?

- Carpet Sweeper – Melville Bissel

- Four Stroke Engine – Nikolaus August Otto

- Telephone – Alexander Graham Bell

- The Tattoo Machine – Thomas Edison

- Synthesizers – Elisha Gray

- The Airbrush Tool – Francis Edgar Stanley